All MSM engines are designated as “double-acting” engines in that they direct pressure steam into both the top and bottom of the cylinder controlled by an appropiate valve mechanism to extract the maximum energy out of the steam supply and provide smoother power delivery.

The twin-cylinder oscillators (Clyde & Avon) are able to control both output shaft speed and reversing, using a single RC servo. They have small multiple flywheels that are offen not recognised as such. There is no need for an additional flywheel for these engines.

The Tyne oscillator is fitted with a separate flywheel.

All the slide valve engines (referred to frequently as "The Big 4"), are available with and without reversing gear. Only the twin cylinder slide valve engines have Radio Control (RC) control options (Mildura & Gem). These are generally more powerful than the oscillating engines, and require more powerful boilers.

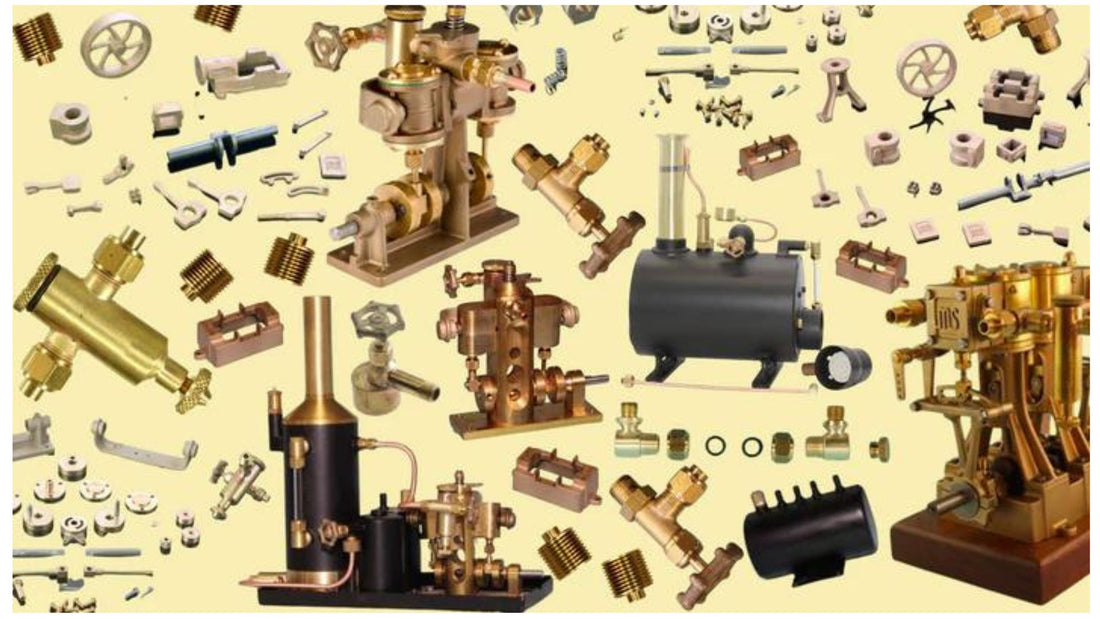

The majority of the components used in "The Big 4" engines are identical for all engines, except the base, crankshafts and some minor parts in the reversing systems. This enables more economical production runs for components, smaller inventories and faster turn around times for special orders.

The Stephensons reversing gear is fitted to the slide valve engines. It provides a measure of speed control, but it is recommended that a separate RC-controlled valve be fitted in the steam line, if fine control of engine speed is required. This can be a simple valve in the steam supply line or, in advanced installations, a valve that can be manually set for a constant steam pressure (i.e. engine power) and it regulates the gas supply to the boiler to minimise the consumption of gas and water.

The "Big 4" engines can be fitted with either a "spoked" or "marine" flywheel.

The spoked flywheel is a classic design that is mostly suitable for static installations. The flywheel projects below the base line of the engine and must be mounted on a block for free running. Since space is always an issue with engines, we normally supply a low profile solid flywheel for the steam plants.

The whole MSM engine range is suitable for static ("bench top") installations. Blog 14. Twin MSM Pevensey Slide Valve Engines" and 16. Alberts' Bench Top Steam Plant have excellent examples of "bench top"steam plants.