Our boiler sizes are defined by the diameter of the boiler body.

They come in 2", 3" & 4" diameters and all have a center-flue design for heating the boiler.

The 2" range has a special vertical design called the "Econo" boiler.

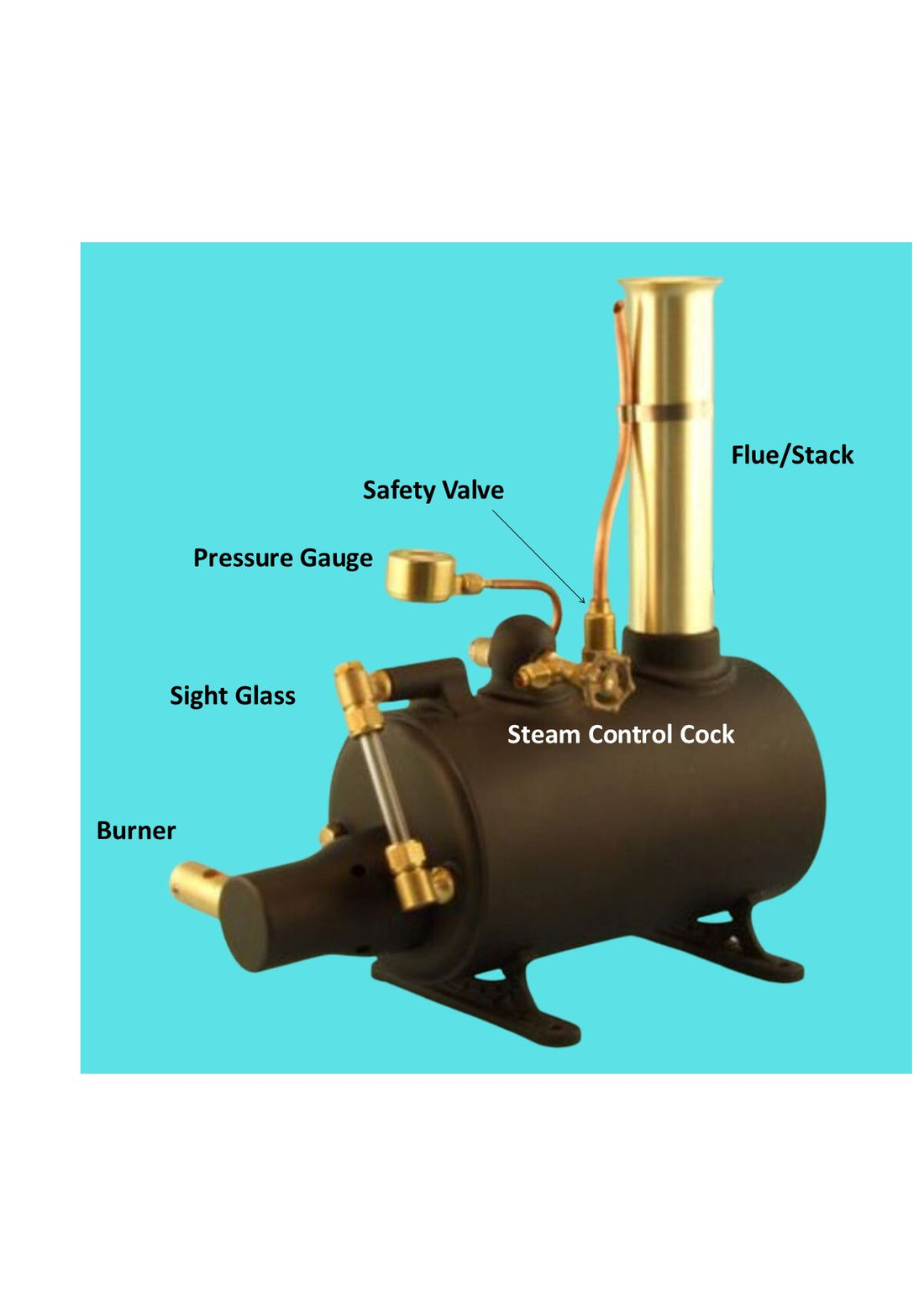

The other 2" & 3" boilers have common features as illustrated in the following pictures.

The 4" boiler is only available as a horizontal design and is similar to the 3" horizontal boiler shown - just bigger.

Following are pictures of three inch 3” horizontal and vertical boilers.

The ceramic burner (image below) shapes the flame, and projects into the center flue to heat the water in the boiler. Inside the boiler, the center flue has a series of cross pipes that increase the area of water subjected to heating, making steam generation more efficient.

Following is a typical view of the cross tubes look like inside the center flue, in a vertical boiler, viewed from the bottom.

The brass item at the rear of the burner pictures above is one part of the air/gas mixture adjustment mechanism used to "calibrate" the burner. This can be better seen in the image following, as part of the gas pipe assembly.

The gas pipe can be connected by a knurled nut at one end, to be screwed to a refillable gas tank for marine operations, or the special valve shown on the left for connecting to a master gas tank for non marine plants.

The other end carries the gas jet and is used to adjust the air/gas mixture when setting up the burner.

All the boilers, except the 2"vertical "Econo" boiler have identical items, each scaled to the size of the boiler.